For OEMs,

the Benefits of Ocular3D are Clear

-

STAY SAFE

Accurate compliance for all domestic and export safety requirements -

STAY COMPLIANT

Liability avoidance with complete virtual validation reporting documentation -

STAY ACCURATE

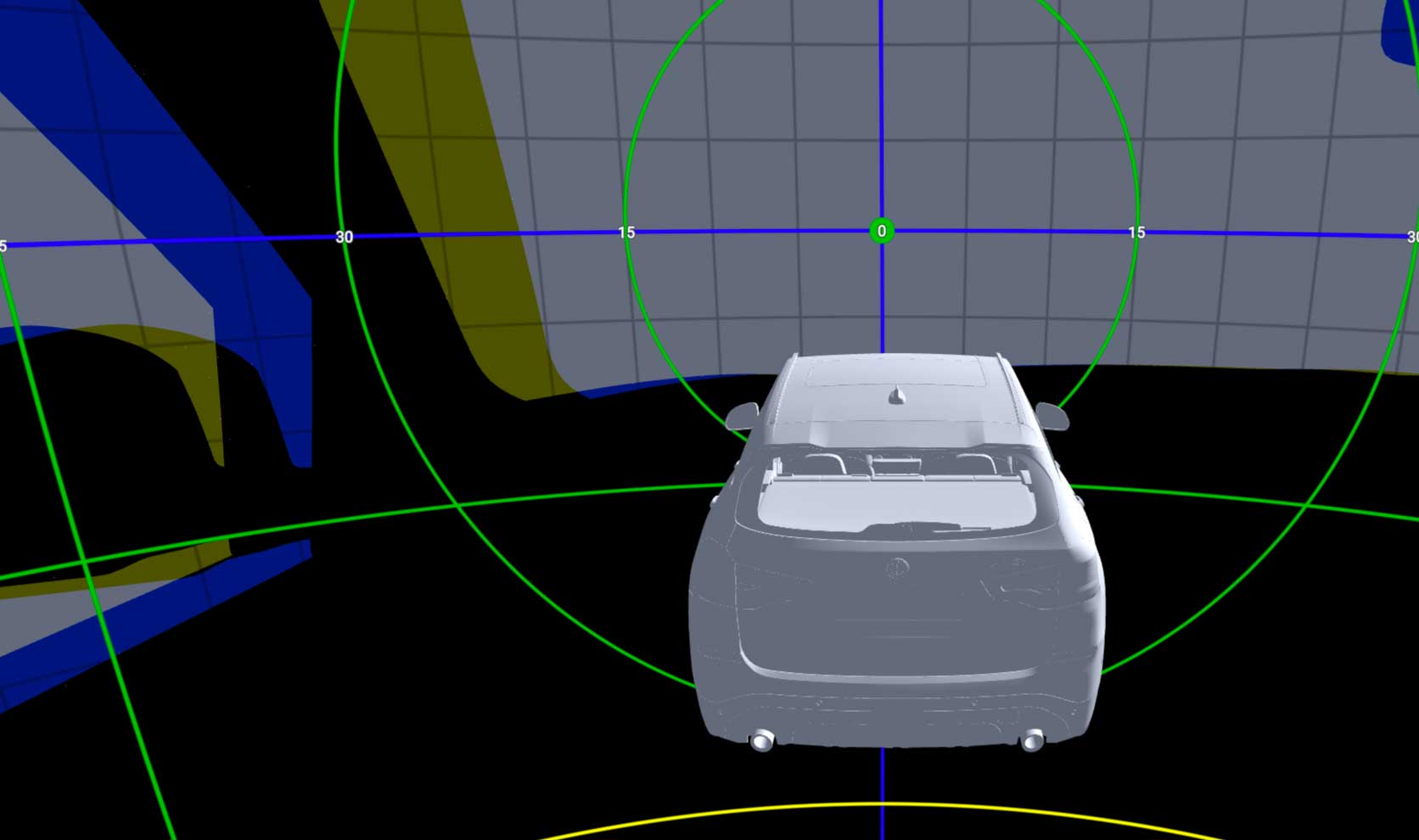

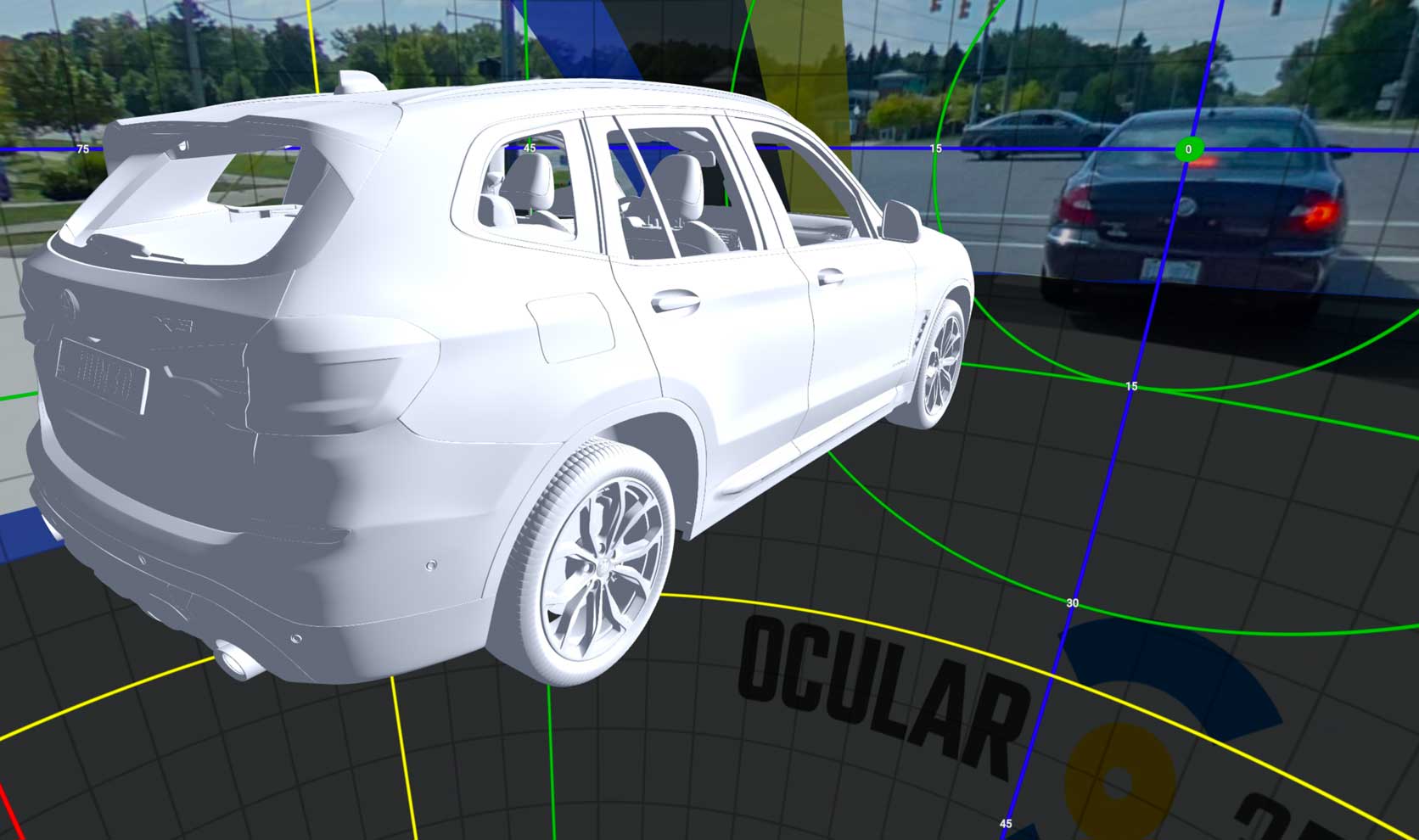

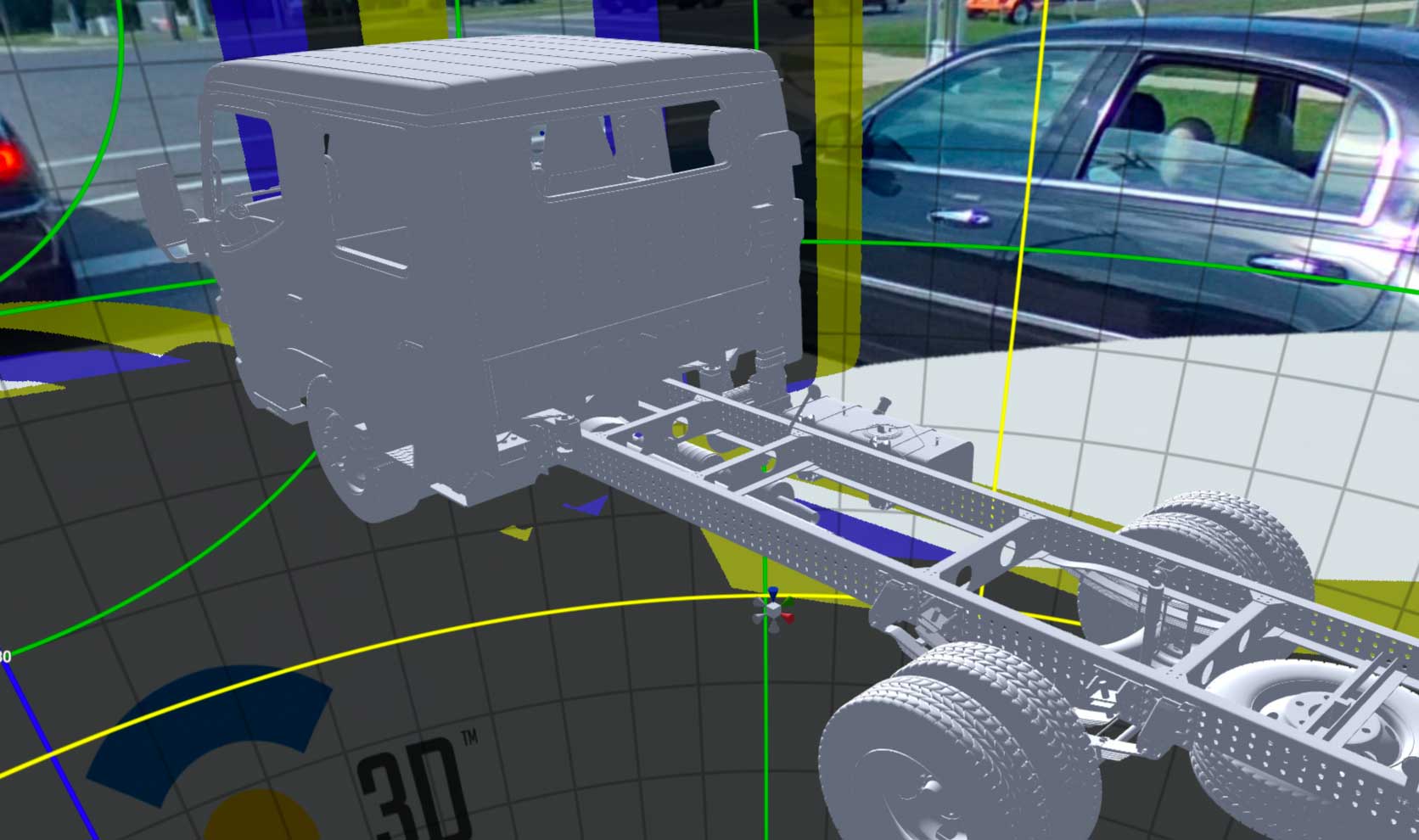

Quantified 3D Visualization Analyses™ gives teams mathematical precision and quick design validation -

STAY COMPETITIVE

Go to market faster with rapid Visualization Analyses™ throughout the iterative design process -

STAY INNOVATIVE

Continuously surprise and delight customers with cutting-edge vehicle designs that lead the industry -

STAY NIMBLE

Complex real-time Visualization Analysis™ gives small, elite teams the power to keep design cycles rapidly moving forward

Some of the Biggest Ocular3D Solutions for OEMs

Problem 1

Billions of Dollars Lost in Unnecessary Engineering Changes

Poorly analyzed designs lead to failing components going to tooling. The inability to analyze early and/or often in the design cycle of a product results in expensive tooling changes. Production of these components leads directly to recalls, costing you billions more.

Ocular3D solves this through:

- The ability to run virtual validations before expensive physical prototyping and capital tooling investment

- Rapid and iterative virtual Visualization Analyses™ throughout the entire build cycle in minutes, not hours

- Empowering leadership to make real-time, accurate business decisions with quantifiable data

- Global and cross-departmental access allowing departments to always be on the same page (Engineering, Legal, etc.)

- Cost avoidances with vastly reduced recalls due to non-compliance issues

- Eliminating the need for costly physical vision bucks and studios

Problem 2

Inefficient Design Processes Add Weeks, or Even Months, to Overall Build Timing

Prolonged traditional analysis methods fall short—time is money, so the best way to save money is with improved 3D Visualization Analysis™ methods.

Ocular3D solves this through:

- Faster build cycles that go to market faster

- Simplifying overall workload across Studio, Human Factors, Design, and Engineering departments

- Creates product design and engineering efficiencies through reporting in minutes, not days

- Cost avoidances with less rework

- Providing product quality improvements through machine learning (ML)

- Comparing evaluations to OEM "Best Practices" for internal process improvements

Problem 3

Vehicle Compliance Mandates are Difficult to Prove

Fulfilling multiple domestic and export mandates with quantifiable data is extremely difficult with the current geometric-based tools methods.

Ocular3D solves this through:

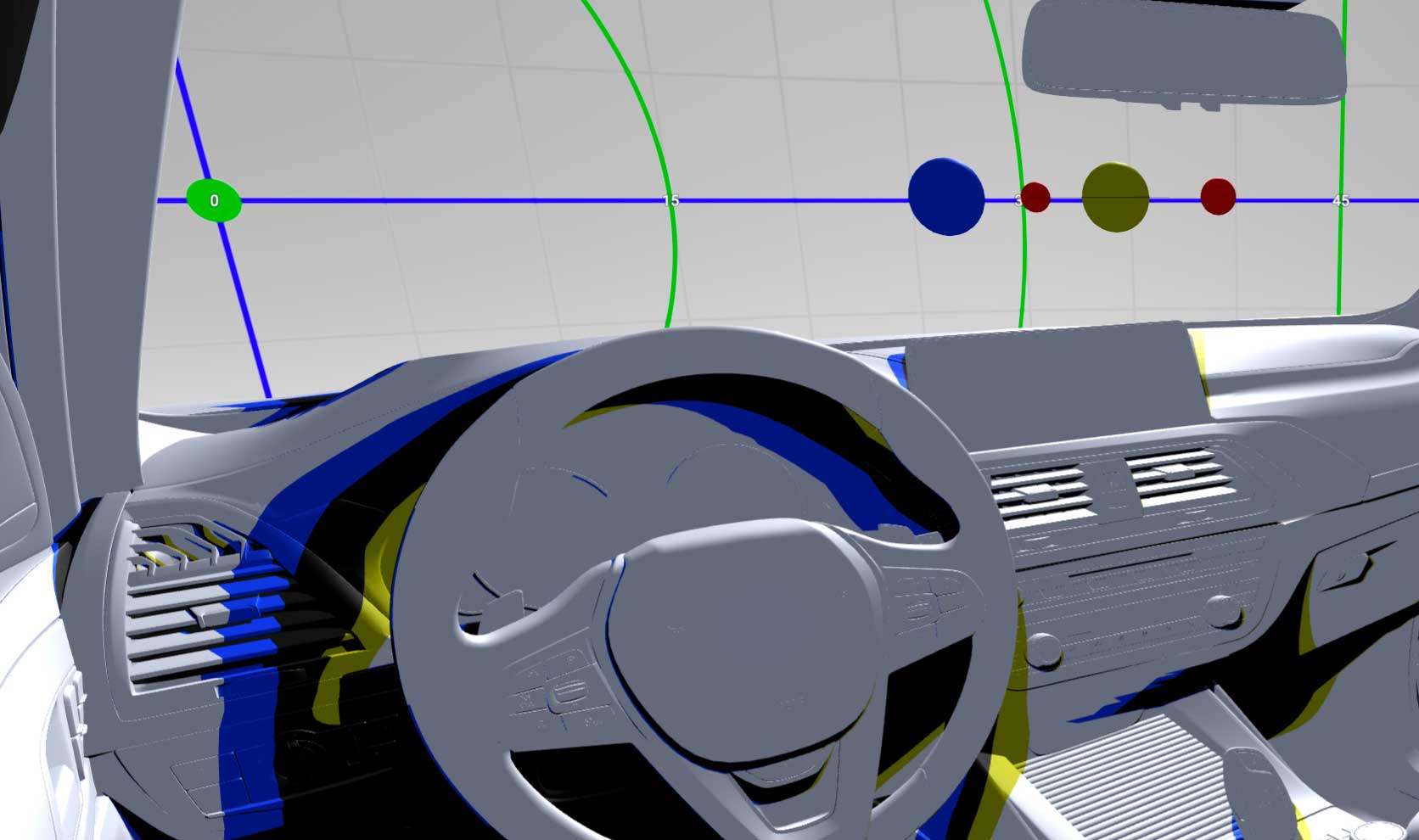

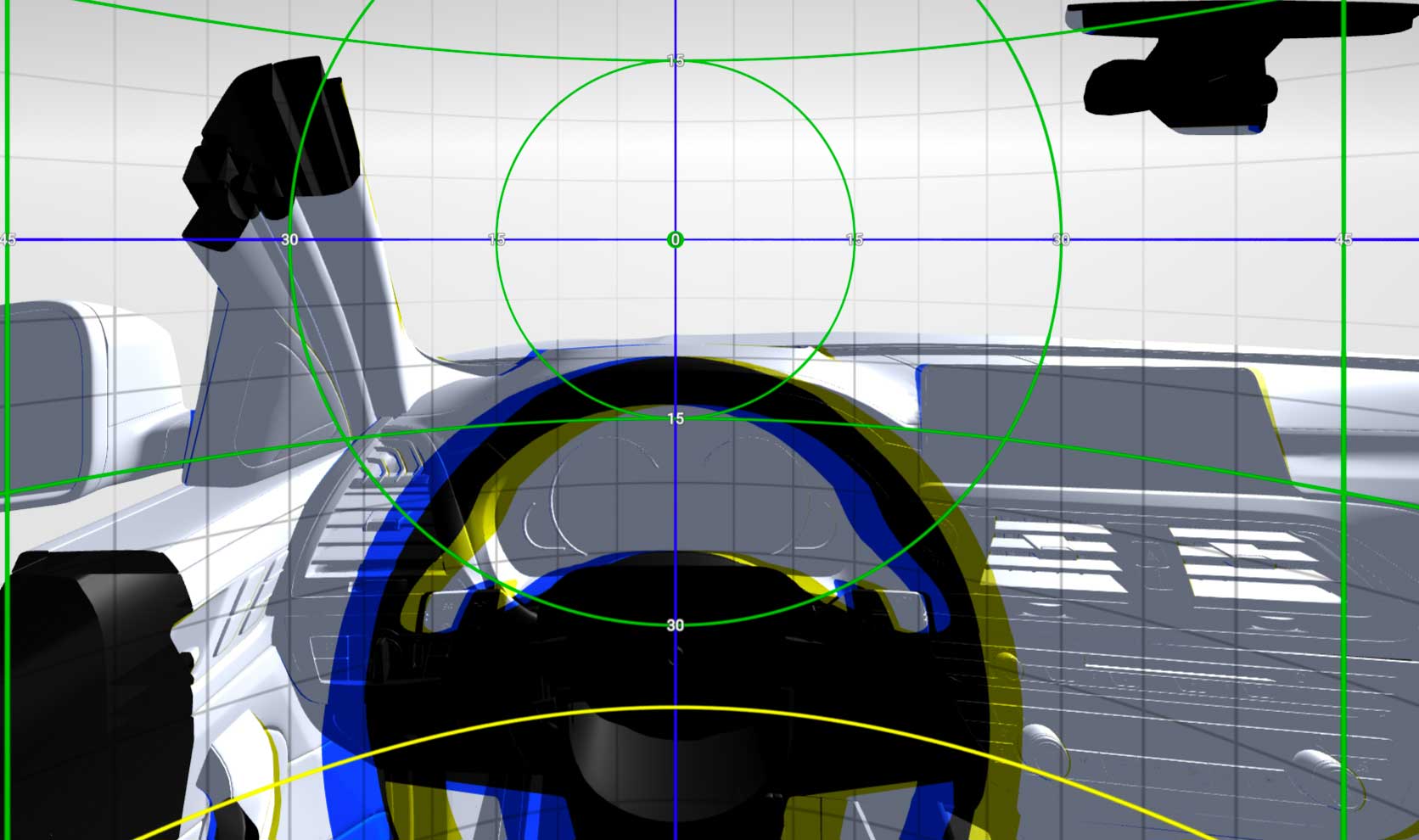

- Global virtual validation tools that calculate any Visualization Analysis™ inside and outside the vehicle

- Being the only digital Visualization Analysis™ safety compliance tool on the market

- SAE recommended practices in the software

- 3D virtual validation and regulatory compliance assessments

- Meeting federal mandatory FMVSS / ECE requirements to sell vehicles within specific regions

- Math-based virtual validation reports for regulatory compliance

Problem 4

Current Methods Require PHD/MS Level-Education Combined with Years of Subject-Matter Expertise

Analytical design reviews are, in most cases, one-to-many. Because current analysis tools are difficult to master, most engineering teams have few members that truly understand the results.

Getting the right tools in the right hands of a larger engineering team allows collective expertise with more eyes on the accuracy of the results.

Ocular3D solves this through:

- Multi-functional team design reviews

- Replacing user-dependent geometry interactions with real-time iterative evaluations

- Ease of use—anyone can be up and running in Ocular3D in minutes

- AR/VR/MR technology provides easy to understand 3D Visualization Analysis™ results, transforming all your engineers into subject-matter experts

- Storing comparative criteria to support ongoing continuous improvement efforts

Problem 5

Building Geometric-Based Analysis Tools Internally is Expensive and Time Consuming

OEMs did not set out to be software companies. However, the geometric-based software tools that you need do not exist on the market today, forcing OEMs to attempt to build them in-house.

Developing geometric-based software tools is very expensive, time consuming, and often happens after the fact.

Ocular3D solves this through:

- Replacing all internal, geometric-based, 2D/3D vision tools

- A flexible Visualization Analysis™ platform that allows for the development of additional analysis types to meet any internal OEM design requirements with far less overhead and effort

- Allowing for endless API expansion possibilities

- Seamless integration with OEM PLM system workflow

- AR/VR/MR technology that provides accurate and repeatable 3D vision criteria