Current Analysis Methods

Current geometry based design practices are time consuming, difficult to initiate, resource intensive and are typically accompanied with a lengthy list of design study requests per subject area. These methods often result in low accuracy, low confidence and lack repeatability.

Current design reviews experience decision churn with these traditional methods. Corrective actions and time sensitive decisions are often delayed by these limitations and typically create a need for more study requests to help build confidence in the result.

Ocular3D Analysis Advantage

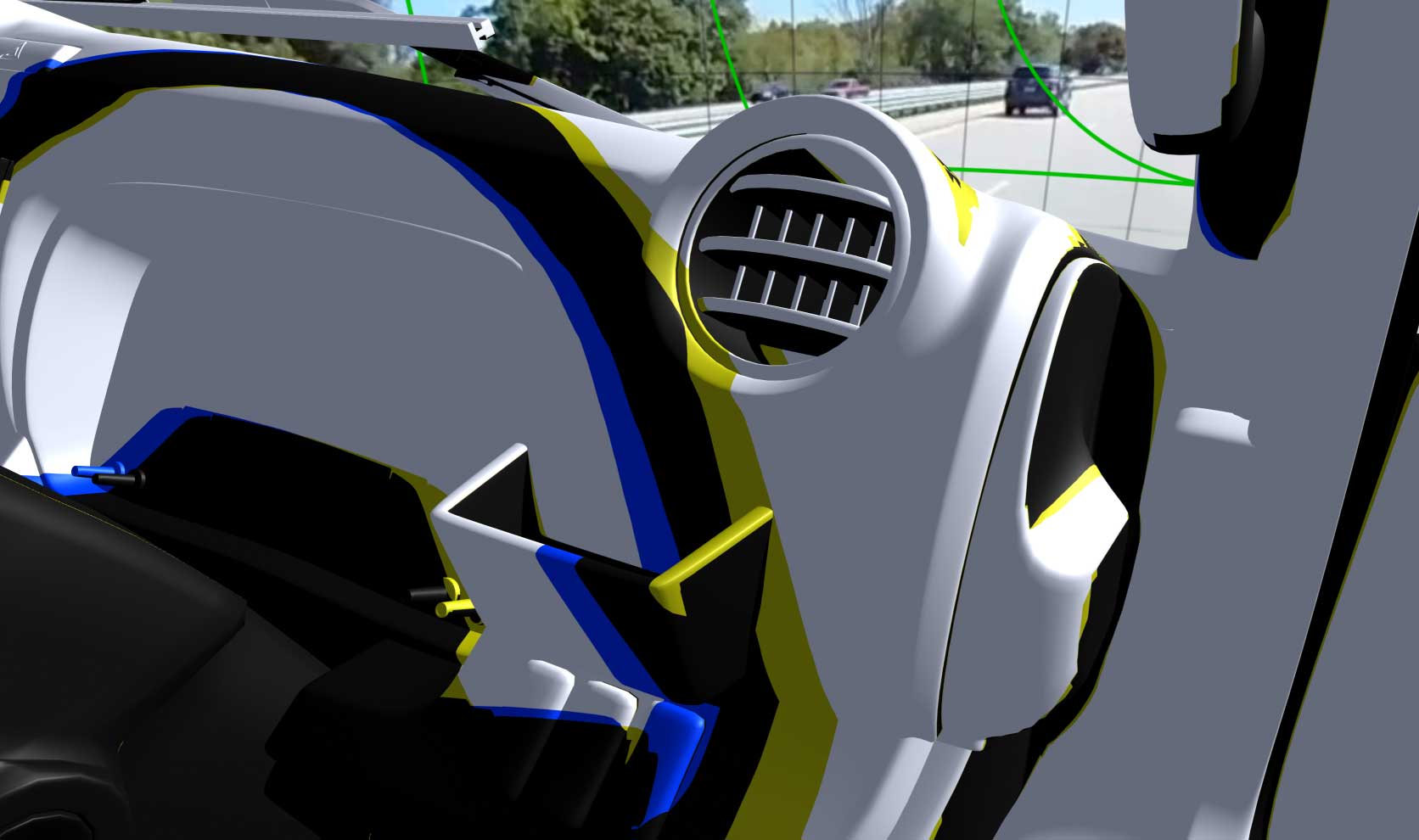

Ocular3D gap and surface quality results are derived from a complex combination of OEM best practice criteria, SAE-recommended practices, and real-world anthropometric data. They generate qualitative 3D Visualization Analyses™ quickly and accurately.

Necessary Guidelines

Ocular3D Meets

Ocular3D ensures compliance with the following standards and recommendations:

- SAE J1050 Describing and Measuring Driver’s Field of View

- SAE J941 Motor Vehicles Drivers’ Eye Locations

- ECE V1/V2

- FMVSS 101 Controls and Displays

- Alliance of Automobile Manufacturers (AAM) principal driver performance

- Driver distraction

- Occupant accommodation

- OEM best practices

- OEM human factors

For OEMs, the Benefits of Using Ocular3D for Gap and Surface Quality Analysis are Clear

- Corrective actions and time sensitive decisions are made with global confidence, first time, every time

- Faster build cycles that meet critical go-to-market deadlines faster

- Complex matters made simple for all user experience levels

- Design efficiencies through qualitative reports in minutes, not days

- Real data calculations act as the subject matter expert covering all best practice and guideline criteria

- Detailed visibility to product quality improvements