Current Analysis Methods

Forward-vision analyses (180° field of view) are complex and time consuming, leaving OEMs behind on domestic and export compliance reporting. Early identification of non-compliances reduces recalls and millions of dollars in liability litigations.

Ocular3D Analysis Advantage

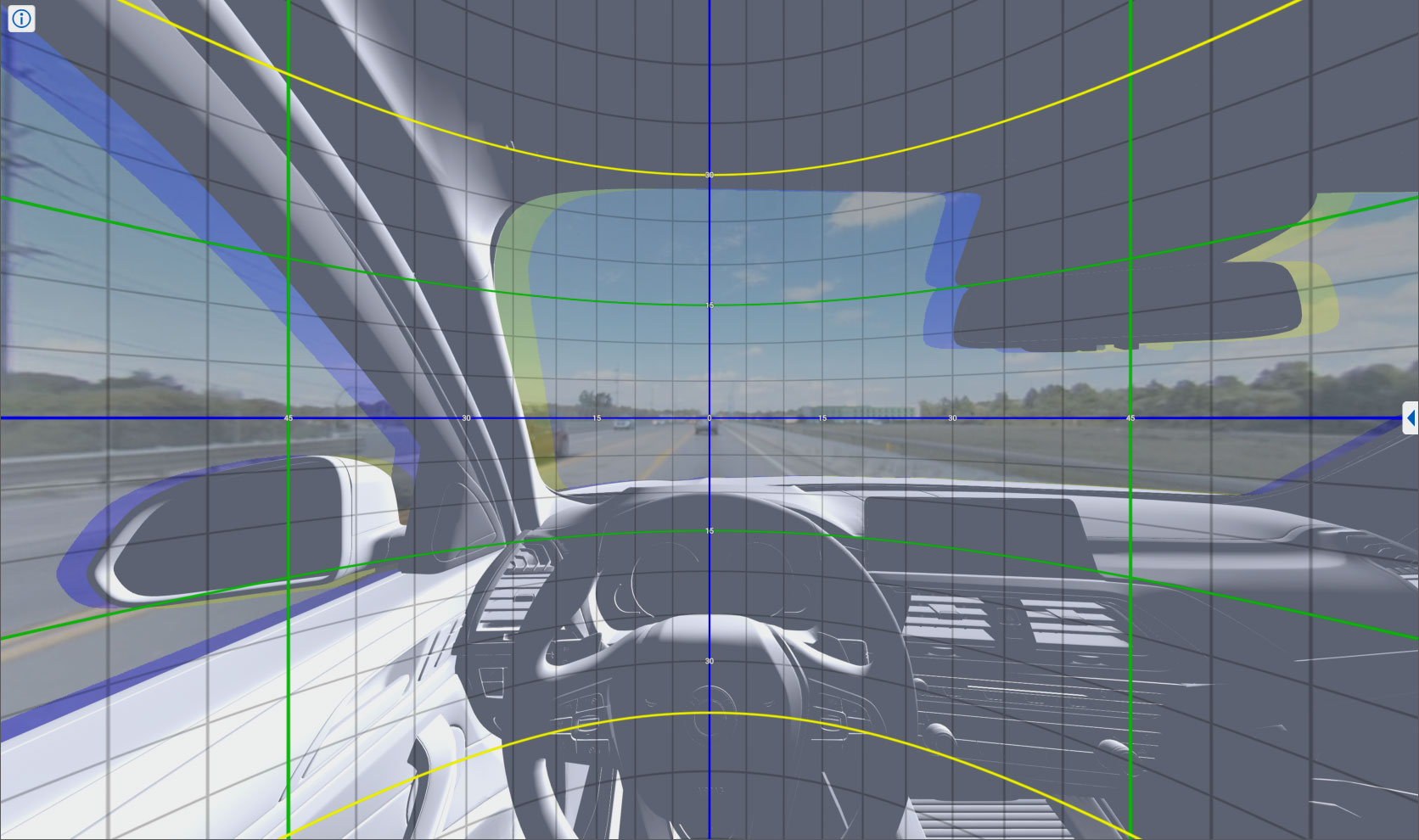

Ocular3D’s Vision Solver™ uses machine learning algorithms to run Visualization Analysis™ of any 3D virtual environment and resultant fields of view. It mimics the driver’s view of the instrument panel surface, displays, steering wheel, hub, and spokes, allowing users to pinpoint all obscurations and verify compliances.

Ocular3D gives you the ability to verify forward-vision compliance in minutes, not days, through every iteration of the design cycle.

Necessary Guidelines

Ocular3D Meets

Ocular3D calculates and reports for all SAE and ECE guidelines:

- FMVSS 101

- NHTSA

- SAE [J941'97] 95th and 99th

- OEM Internal Vision Criteria Guidelines

- ECE V1 & V2

- User defined

For OEMs, the Benefits of Using Ocular3D for Forward Vision Analysis are Clear

- No more manual CAD techniques with lines and curves.

- Rapid, quantifiable, and compliant iterative capabilities help you head off design issues as you go.

- Design cycles no longer experience multi-day vision analysis delays.

- The ability to actually see the effects of obstructions allows designers and engineers to better understand them.

- Reporting that calculates compliant Visualization Analysis™ verifying vehicle safety.

- Conducting additional Visualization Analysis™ types beyond the current capabilities.